In Stock & Ready to Ship

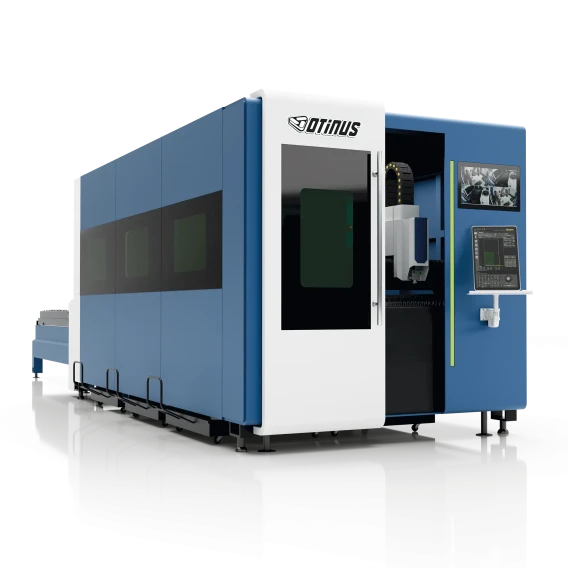

Machines for Your Production

Align the machine with your business strategy. The Base line optimizes your budget, while the Pro series delivers uncompromising power. Both come with a smooth start: financing options, training, and service. You gain a turnkey solution that ensures production stability and predictable output.

Select a series

Schedule a Live or Virtual Demo

Visit our showroom or book an online presentation that fits your schedule.

Schedule a Live or Virtual Demo. Visit our showroom or book an online presentation that fits your schedule.

More Than Just Machines

Partnership That Streamlines Your Business

We prioritize solutions that respect your time and capital. Operating directly from Bloomingdale, IL, we adapt demo schedules to your needs. Our fully stocked local warehouse and financing options simplify the buying process to the absolute minimum. We deliver ready-to-work tools, eliminating unnecessary barriers.

Experience

That Pays Off

That Pays Off

Otinus.

Your Partner

in Metalworking

Benefit from the support of a global brand. Since 2010, we have been empowering manufacturers in Europe and the US by delivering proven machinery and comprehensive service. We focus on innovation, training, and accessible financing so you can operate without downtime. At Otinus, we don’t just sell equipment – we provide the expertise and support needed to grow your business.

The Numbers Speak for Themselves

What’s New at Otinus?

Step Inside the Future of Metal Fabrication — Join Otinus Open House in Bloomingdale, IL!

Can CNC machines be inspiring? Absolutely — especially when you can see them running live, talk directly with real experts (no corporate slide decks in sight), and enjoy a delicious Polish lunch along the way.

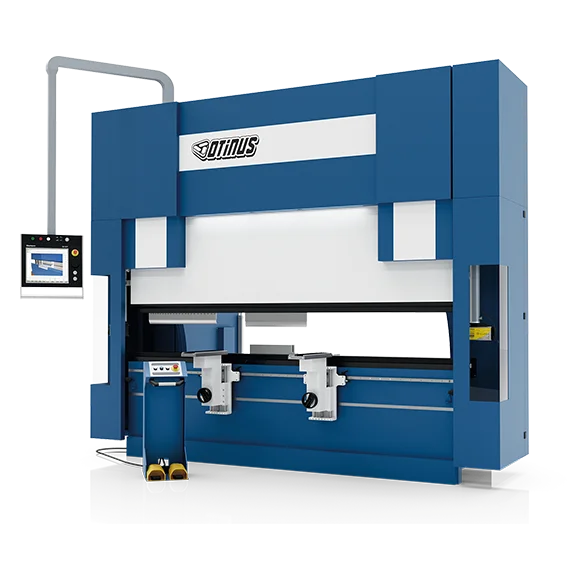

Press Brake PBO-3212-CNC and Guillotine Shear SMO-3206-N

We have completed another order in which we delivered the PBO-3212-CNC press brake and the SMO-3206-N guillotine shear to our Customer. The project included comprehensive support—from safe transportation and precise machine installation to practical training for the operator team.

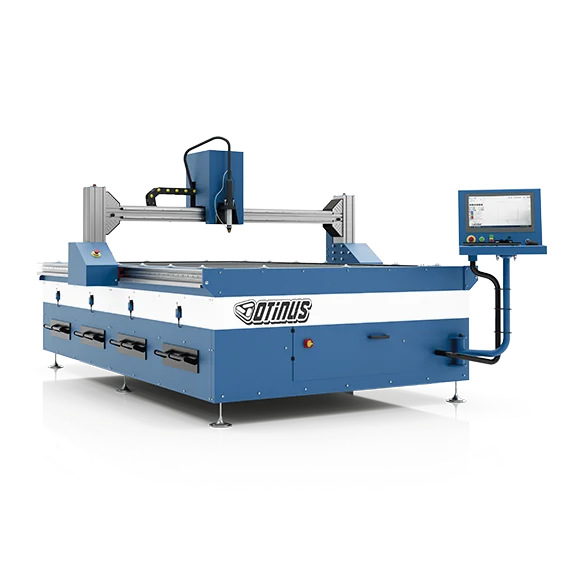

CNC Plasma Cutting Machine PCO-3015-D

We have completed another comprehensive CNC technology implementation for our Customer. As part of the project, we delivered, installed, and commissioned the PCO-3015-D CNC plasma cutting machine, operating in combination with the renowned Hypertherm Powermax 105XP plasma power source.

Hydraulic Press Brake PBO-2563-CNC

We have completed another technological implementation, confirming our comprehensive approach to customer service. This time, we delivered the PBO-2563-CNC hydraulic press brake, providing a full scope of services—from transportation and professional installation to hands-on operator training.

Plasma Gases – A Practical Guide

Depending on the type of material being processed, gas selection is critical to overall efficiency. The right gas influences not only cutting speed and quality, but also consumable life and operating costs.

In this guide, we explain the combinations, characteristics, and benefits of various plasma and shielding gases.

How Does a Plasma Cutter Work?

What Components Make Up a Plasma Cutter?

Power Supply

Powered from the electrical grid, it generates direct current (DC) with a voltage between 240 and 400 V.

The total rated power and current capacity of the power supply have a crucial impact on the maximum cutting thickness.

Its primary task is to provide sufficient energy to initiate the arc.

What Is Plasma?

A Brief History

Most of us learned in school about only three states of matter. This is because plasma began to be commonly discussed in this context relatively recently.

The first research on plasma was conducted in 1928 by American physical chemist, Nobel laureate, and pioneer of gas-discharge studies — Irving Langmuir.

What Is Plasma Gouging?

In this article, you will learn what plasma gouging is and how it works. Enjoy the read.

FABTECH 2024 in Orlando

FABTECH 2024 was a special edition, as it was held for the first time in Orlando, Florida, from October 15–17. The event attracted approximately 30,000 professionals from all 50 U.S. states and 70 countries. More than 1,500 exhibitors, including 279 first-time participants, showcased their products and technologies across 750,000 square feet of exhibition space. Over 500 product launches were presented during the show, and key trends such as automation, robotics, artificial intelligence, 3D printing, and sustainable manufacturing were widely discussed. The event also highlighted the dynamic growth of Florida’s manufacturing sector, which represents a growing share of the state’s economy and generates hundreds of thousands of jobs.

Detroit Auto Show 2025

The Detroit Auto Show (North American International Auto Show) returned to its traditional winter schedule in 2025. The event took place from January 11 to 20 at the Huntington Place exhibition center. The show featured the largest American brands such as Ford, General Motors, Stellantis, and Toyota, alongside manufacturers from Europe and Asia. Visitors could not only admire new vehicle launches, but also take advantage of four test tracks, including dedicated off-road zones and presentations of electric powertrains.

INNOFORM 2025 in Bydgoszcz

INNOFORM is an international trade fair dedicated to the toolmaking industry and plastics processing, recognized as the most important event of its kind in northern and central Poland. The 2025 edition took place from March 4–6 at the Trade and Exhibition Center in Bydgoszcz. The fair is distinguished by a strong exhibitor lineup presenting the latest products and services for the tooling industry, as well as the Industrial Services zone, dedicated to companies involved in the production, machining, and repair of injection molds. In addition to the exhibition, the event features conferences, panel discussions, and a cooperation exchange, which has allowed INNOFORM to quickly build a strong brand and attract significant interest from entrepreneurs.

Aeromart Montreal 2025

Aeromart Montreal is a recurring event dedicated to the aerospace and aviation industry, held every two years in the capital of the Province of Quebec. The 2025 edition, scheduled for March 25–27 at the Palais des Congrès de Montréal, marked the ninth edition of this international business forum. Aeromart brings together aircraft manufacturers, tier suppliers, airline representatives, and research institutions. The program includes pre-arranged B2B meetings, panel discussions, presentations of new technologies, and an exhibition area showcasing innovations in materials, mechanics, and electronics.

Step Inside the Future of Metal Fabrication — Join Otinus Open House in Bloomingdale, IL!

Can CNC machines be inspiring? Absolutely — especially when you can see them running live, talk directly with real experts (no corporate slide decks in sight), and enjoy a delicious Polish lunch along the way.

FABTECH 2025 in Chicago

A record-breaking edition of the largest industrial trade show

FABTECH 2025, once again held in Chicago in September, proved to be the largest and most dynamic edition in the event’s history. Over 42,000 professionals from the manufacturing and metalworking industries visited the McCormick Place exhibition center to meet with more than 1,700 exhibitors. Across 885,000 square feet of exhibition space, hundreds of machines and systems were showcased, including over 300 first-time exhibitors. Visitors were able to see more than 800 product launches and take part in over 200 educational sessions, panel discussions, and workshops. Organizers estimate that the event generated more than USD 80 million in economic impact for the city.

The Revolutionary Powermax SYNC System

The Powermax SYNC™ series represents the next generation of Powermax 65®, 85®, and 105® systems. Designed with an integrated logic module and a groundbreaking one-piece consumable cartridge, Powermax SYNC sets a new standard for plasma cutting technology.

Hypertherm Plasma Cutters – Applications

Hypertherm Powermax plasma cutters are known not only for their high quality, but also for their wide range of applications. Various available torches and consumables make it possible to adapt these versatile systems to many different processes.

Selecting the proper equipment is crucial to achieving optimal workflow efficiency. The choice of gases also plays a significant role in plasma cutting and gouging performance.

In this article, we will discuss the diverse applications of Powermax plasma systems from leading manufacturer Hypertherm.

Is Operating a Plasma Cutting Machine Difficult?

When we observe older individuals who grew up in a world without advanced technology and hand them a mobile phone for the first time (not necessarily a smartphone), what reaction do we usually see? Confusion, stress, reluctance, and a sense of unfamiliarity.

Unfortunately, the fear of new technology is not limited to seniors.

It can appear in any of us when we are faced with operating a device we’ve never used—or anything similar—we have no prior reference for.

How Does a Plasma Cutter Work?

What Components Make Up a Plasma Cutter?

Power Supply

Powered from the electrical grid, it generates direct current (DC) with a voltage between 240 and 400 V.

The total rated power and current capacity of the power supply have a crucial impact on the maximum cutting thickness.

Its primary task is to provide sufficient energy to initiate the arc.

Authorized Hypertherm Dealer — Why It Matters

Why should you purchase Hypertherm products from an authorized seller?

In this article, we explain the advantages of choosing a trusted and certified source of plasma solutions — an authorized Hypertherm dealer.

CNC Plasma Cutting Machine PCO-3015-D

We have completed another comprehensive CNC technology implementation for our Customer. As part of the project, we delivered, installed, and commissioned the PCO-3015-D CNC plasma cutting machine, operating in combination with the renowned Hypertherm Powermax 105XP plasma power source.

Hydraulic Press Brake PBO-2563-CNC

We have completed another technological implementation, confirming our comprehensive approach to customer service. This time, we delivered the PBO-2563-CNC hydraulic press brake, providing a full scope of services—from transportation and professional installation to hands-on operator training.

Hydraulic Guillotine Shear SMO-3206-N

We have completed another successful implementation at our Customer’s facility, covering delivery, installation, and comprehensive operator training. This time, the machine park was expanded with the SMO-3206-N hydraulic guillotine shear—a solution designed for precise and efficient sheet metal cutting in everyday production.

CNC Plasma Cutting Machine PCO-2010-B

We have completed another comprehensive implementation for a customer, including the delivery, installation, and operator training of the PCO-2010-B CNC plasma cutting machine

Hypertherm Cares About the Environment

For Hypertherm, the idea that “less is more” applies not only to internal development, but—above all—to the world around us. Many global corporations still struggle to align their operations with environmental responsibility. This is why initiatives undertaken by companies like Hypertherm deserve genuine recognition and support.

Plasma Gases – A Practical Guide

Depending on the type of material being processed, gas selection is critical to overall efficiency. The right gas influences not only cutting speed and quality, but also consumable life and operating costs.

In this guide, we explain the combinations, characteristics, and benefits of various plasma and shielding gases.

Plasma Cutting vs. Oxy-Fuel Cutting: Which Should You Choose?

Oxy-fuel cutting is a widely used thermal method in metal processing. Plasma cutting, on the other hand, is a younger and far more modern technology that is gradually gaining dominance in the market.

But is plasma the answer to all manufacturing challenges?

Machine Financing — How Can It Be Done?

Good news: every one of our sheet-metal processing machines can be purchased through leasing, a loan, or bank credit.

Below is a short overview of how each of these financing methods works.

FABTECH 2024 in Orlando

FABTECH 2024 was a special edition, as it was held for the first time in Orlando, Florida, from October 15–17. The event attracted approximately 30,000 professionals from all 50 U.S. states and 70 countries. More than 1,500 exhibitors, including 279 first-time participants, showcased their products and technologies across 750,000 square feet of exhibition space. Over 500 product launches were presented during the show, and key trends such as automation, robotics, artificial intelligence, 3D printing, and sustainable manufacturing were widely discussed. The event also highlighted the dynamic growth of Florida’s manufacturing sector, which represents a growing share of the state’s economy and generates hundreds of thousands of jobs.

Detroit Auto Show 2025

The Detroit Auto Show (North American International Auto Show) returned to its traditional winter schedule in 2025. The event took place from January 11 to 20 at the Huntington Place exhibition center. The show featured the largest American brands such as Ford, General Motors, Stellantis, and Toyota, alongside manufacturers from Europe and Asia. Visitors could not only admire new vehicle launches, but also take advantage of four test tracks, including dedicated off-road zones and presentations of electric powertrains.

INNOFORM 2025 in Bydgoszcz

INNOFORM is an international trade fair dedicated to the toolmaking industry and plastics processing, recognized as the most important event of its kind in northern and central Poland. The 2025 edition took place from March 4–6 at the Trade and Exhibition Center in Bydgoszcz. The fair is distinguished by a strong exhibitor lineup presenting the latest products and services for the tooling industry, as well as the Industrial Services zone, dedicated to companies involved in the production, machining, and repair of injection molds. In addition to the exhibition, the event features conferences, panel discussions, and a cooperation exchange, which has allowed INNOFORM to quickly build a strong brand and attract significant interest from entrepreneurs.

Aeromart Montreal 2025

Aeromart Montreal is a recurring event dedicated to the aerospace and aviation industry, held every two years in the capital of the Province of Quebec. The 2025 edition, scheduled for March 25–27 at the Palais des Congrès de Montréal, marked the ninth edition of this international business forum. Aeromart brings together aircraft manufacturers, tier suppliers, airline representatives, and research institutions. The program includes pre-arranged B2B meetings, panel discussions, presentations of new technologies, and an exhibition area showcasing innovations in materials, mechanics, and electronics.

Press Brake PBO-3212-CNC and Guillotine Shear SMO-3206-N

We have completed another order in which we delivered the PBO-3212-CNC press brake and the SMO-3206-N guillotine shear to our Customer. The project included comprehensive support—from safe transportation and precise machine installation to practical training for the operator team.

CNC Plasma Cutting Machine PCO-3015-D

We have completed another comprehensive CNC technology implementation for our Customer. As part of the project, we delivered, installed, and commissioned the PCO-3015-D CNC plasma cutting machine, operating in combination with the renowned Hypertherm Powermax 105XP plasma power source.

Hydraulic Press Brake PBO-2563-CNC

We have completed another technological implementation, confirming our comprehensive approach to customer service. This time, we delivered the PBO-2563-CNC hydraulic press brake, providing a full scope of services—from transportation and professional installation to hands-on operator training.

Hydraulic Guillotine Shear SMO-3206-N

We have completed another successful implementation at our Customer’s facility, covering delivery, installation, and comprehensive operator training. This time, the machine park was expanded with the SMO-3206-N hydraulic guillotine shear—a solution designed for precise and efficient sheet metal cutting in everyday production.