A Brief History

Most of us learned in school about only three states of matter. This is because plasma began to be commonly discussed in this context relatively recently.

The first research on plasma was conducted in 1928 by American physical chemist, Nobel laureate, and pioneer of gas-discharge studies — Irving Langmuir.

Physical Properties

Energy plays a key role in changing states of matter.

When a substance loses energy, the distance between its atoms decreases and molecular motion slows until movement stops entirely.

Two simple everyday examples confirm this principle:

-

Water freezes at low temperatures because it releases energy during cooling.

-

Water evaporates when heated because we supply energy to it.

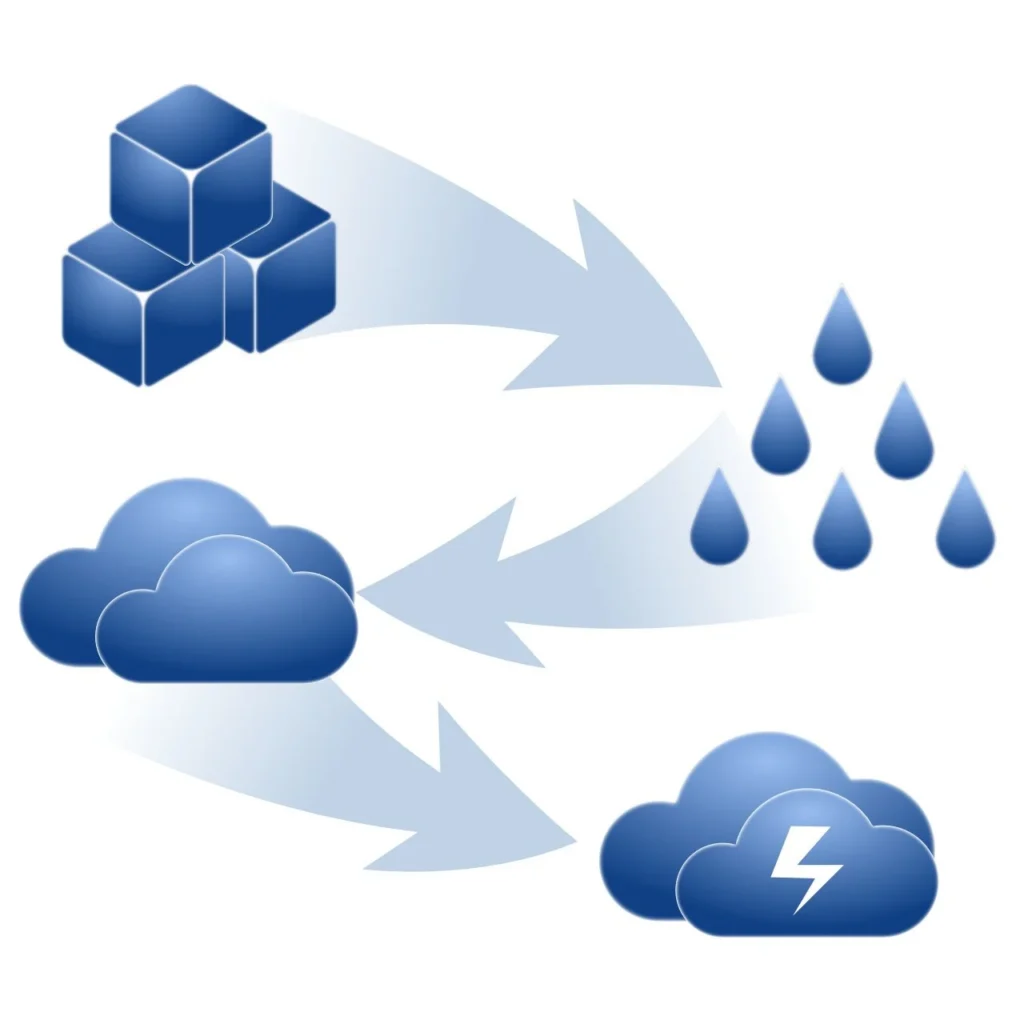

Thus, the four states of matter are:

Solid

Particles are packed tightly. Shape and volume are difficult to change.

Liquid

Volume remains constant, but the substance takes the shape of its container. Particles move freely.

Gas

Gas takes both the shape and volume of its container. Particle spacing is greatest, and their movement is highly dynamic.

Plasma

A state similar to gas, but with a significant portion of particles electrically charged. Plasma’s properties vary depending on the type.

Three Types of Plasma

-

Hot plasma — temperatures above 1 million K; this is the plasma that forms stars.

-

Ring-discharge plasma — difficult to study; generated under high-frequency electromagnetic fields and low pressure.

-

Cold plasma — found naturally on Earth (e.g., electrical discharges) and in human-made devices called plasmotrons. Our plasma cutting systems use this type.

How Is a Plasma Arc Created?

Producing a plasma arc requires three things:

-

Electrodes between which the arc is formed.

-

High voltage — up to 10 kV at about 2 MHz. Surprisingly, such a system can be powered by a standard 230 V AC supply.

-

An inert gas, such as argon, nitrogen or even air, which becomes plasma when heated by the electric arc.

A device built this way is called a plasmotron, and the plasma stream generated inside has extremely high thermal energy density.

Interesting Fact

Another method of creating plasma is shown by a popular science-center gadget: the plasma globe (or plasma lamp), originally designed by Nikola Tesla.

Inside a sealed glass sphere filled with a low-pressure gas, a central electrode is powered by a high-voltage, high-frequency oscillator (approx. 10 kV, 35 MHz).

The electric field ionizes the gas, producing the striking luminous filaments — visible plasma. The globe is purely visual and educational; it has no industrial application.

Plasma in Practice

Two types of plasma arcs can form inside plasma torches:

-

Internal arc — generated between two electrodes.

-

Transfer arc — formed between the torch electrode and the workpiece. This requires the workpiece to be electrically conductive and is the arc used in plasma cutting machines.

Plasma cutting is suitable for metals such as:

-

carbon steel

-

aluminum alloys

-

copper alloys

-

stainless steel (and other high-melting-point materials)

Plasma makes it possible to cut materials that are difficult to melt, like stainless steel or tungsten. Cutting speeds depend on thickness and can reach up to 10 m/min, while thickness capacity can reach up to 60 mm for low-carbon steel.

To achieve high-quality edges, swirling gases are used to constrict the plasma stream. Common gases include oxygen or air for carbon steel, and nitrogen or nitrogen–hydrogen–oxygen mixtures for stainless steel.

There are handheld plasma cutters, similar in appearance to welders, which offer broad practical use. However, because the plasma jet is extremely precise, manual cutting cannot fully exploit its capabilities.

This is where CNC plasma cutting machines excel. They are fast, precise, and allow efficient sheet nesting. A well-configured machine produces smooth edges requiring minimal finishing, significantly speeding up production and improving overall efficiency.

Summary

Plasma is the fourth state of matter, created by heating gas to extremely high temperatures, e.g., by means of an electric arc.

The gas becomes ionized, and its particles carry electrical charge, forming a high-energy stream that can be precisely directed.

Interested in Plasma Technology?

We invite you to explore our product range.

With our plasma systems, you will achieve precise cuts and significantly accelerate production.

The only limit is imagination.

If you have any questions, feel free to email us — we will be happy to help.