Laser cutter or plasma cutter? The type of machine you should choose depends primarily on the projects you intend to carry out. Both machines work well for processing different types of materials. The profitability of investing in either of the above machines will therefore depend on the user’s needs.

When is a plasma cutter the right choice?

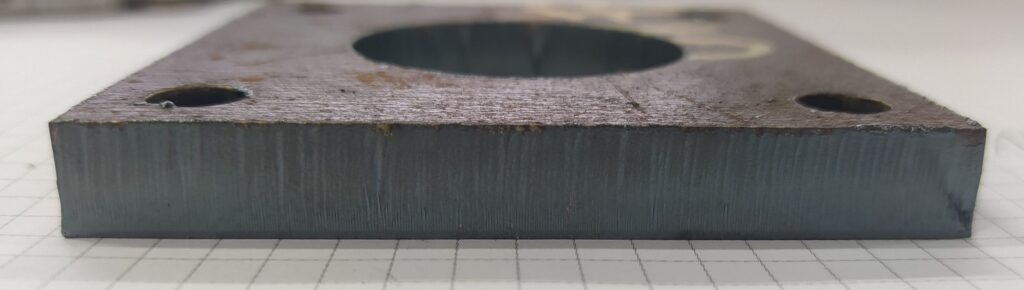

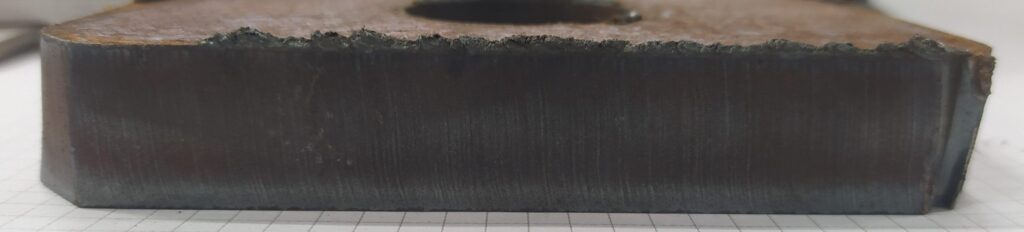

A plasma cutter provides good cutting quality, although it will never match the quality of a laser cutter. If you need simple parts that do not require high precision, the plasma cutter will be completely sufficient for you. It should be remembered that the plasma arc is never perfectly straight. Plasma bevels the cutting edge — meaning that the cut edge will reflect the shape of the arc. Sometimes slight mechanical finishing is required to remove burrs left on the edges of the material. Small deviations in the dimensions of the project may also occur. A plasma cutter is recommended for cutting materials with a thickness of 2 mm and above. It is not suitable for cutting holes smaller than 6 mm, because the quality of such a cut will not be precise. However, when it comes to very thick sheets — here plasma has a significant advantage over laser, which does not perform as well when cutting sheets thicker than 20 mm (depending on the laser power). It is also worth adding that plasma cutters generate significantly lower energy consumption than laser cutters. The costs you must invest in a plasma cutting machine are also much lower.

When is a laser cutter the right choice?

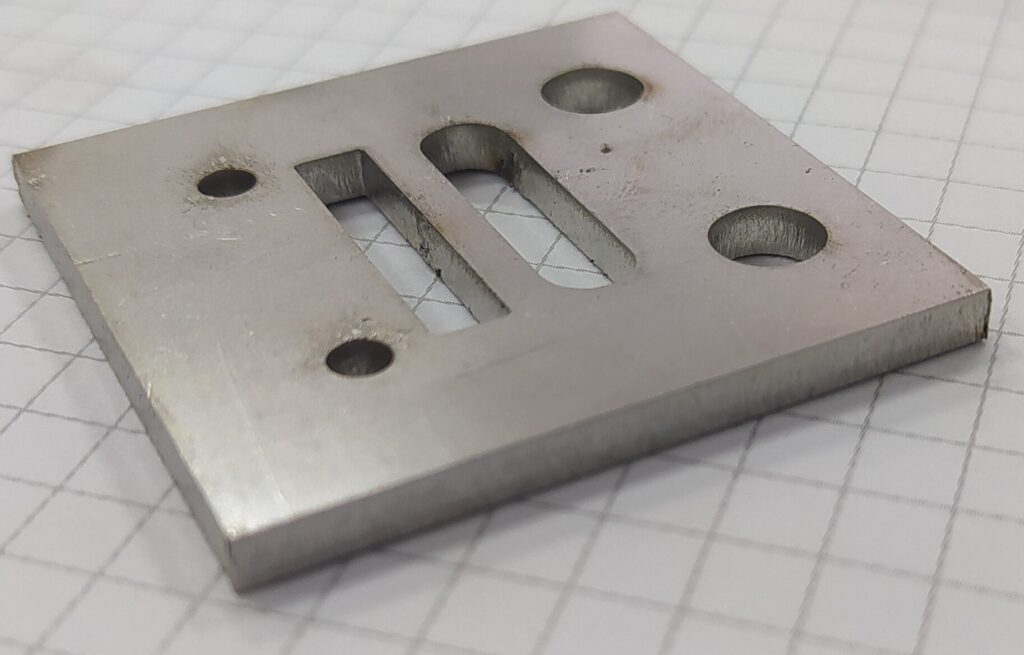

A laser cutter, on the other hand, is ideal for parts that require high precision. A laser is a concentrated beam of light that cuts with very high accuracy. The margin of error is extremely small, and the dimensions are precisely reproduced. All this makes the laser suitable for small and detailed parts. If a part has irregular shapes and/or very small holes, very high cutting quality is required. In this case, the plasma cutter loses to the laser. A laser is capable of cutting holes as small as 0.1 mm in a 1 mm thick sheet. With proper parameter settings, it cuts the part “ready to use,” meaning no further mechanical finishing is required. The cut edge is smooth and free of burrs. In addition, a laser cutter can cut very quickly. When cutting mild steel or stainless steel with thicknesses of 1–2 mm, it reaches travel speeds of up to 25 m/min — by comparison, a plasma cutter reaches such speeds only during rapid moves, meaning without actually cutting. A 4 kW laser can cut mild steel with a thickness of 22 mm (although a laser cutter of this power costs around 500,000).

Comparison

It is not possible to clearly answer which solution is better — buying a plasma cutter or a laser cutter. Everything depends on the specific project to be completed; on what type of production predominates in a given workshop.

In case of doubts or uncertainties, it is best to contact us. Our employees have extensive experience and knowledge about sheet metal processing machines. We will gladly advise which method will be better in your specific situation.

Summary of the key advantages of laser and plasma cutters

Advantages of a plasma cutter:

-

low investment cost (even 5 times lower compared to a laser)

-

low operating cost

-

regardless of the plasma source — cutting mild steel (for the MaxPro200 system) up to 50 mm

-

ideal for production where the accuracy of the cut parts does not need to be perfect, only good

-

ideal for small and medium-sized companies that cannot afford a more expensive machine

Plasma cutter — A new era in precision and cutting efficiency

Advantages of a laser cutter:

-

perfect cutting quality, ability to cut very small details

-

no slag on the cut edge

-

very high cutting speeds

-

unlike plasma, the processed material does not have to be conductive

Machines are available in many configurations: enclosed, open, with exchange tables and/or with a tube cutting attachment.

Laser cutters Otinus