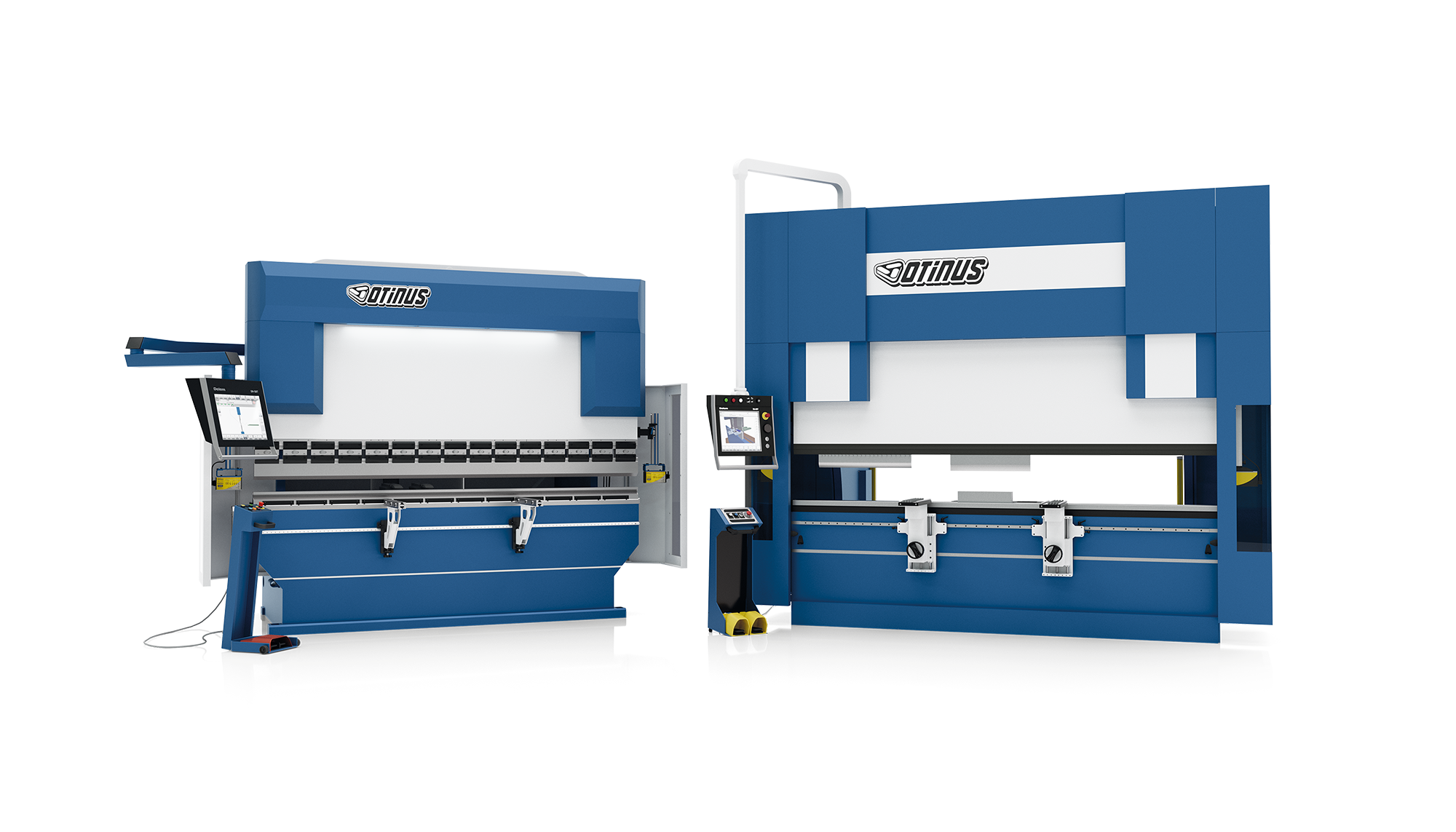

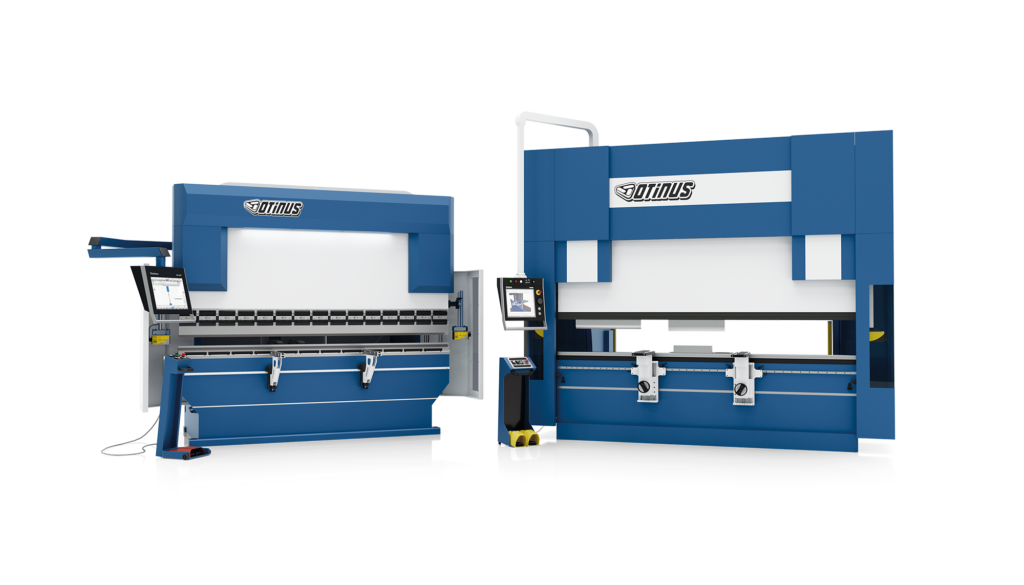

Reliable Press Brakes

Two product lines, two levels of advancement, one Otinus quality.

The BASE series stands for reliability and simplicity at an excellent price. The PRO series delivers maximum automation, higher power, and premium-class control. Both lines share precision, durability, and comprehensive technical support.

Regardless of the scale of your production, you will find a solution tailored to real operational needs.

We Offer Machines That Set New Standards

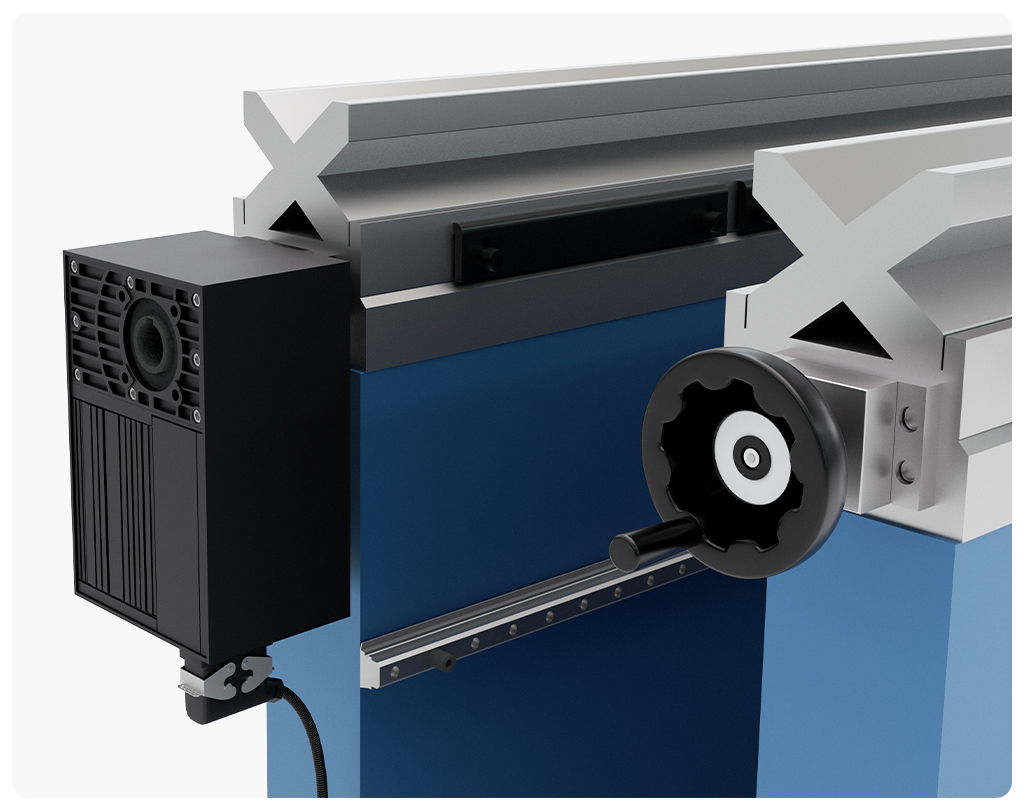

Crowning Compensation

During bending, press brake frames may slightly deflect, affecting angle uniformity along the entire bend length. That is why our machines offer manual or automatic crowning compensation (V-axis).

The manual version is ideal for less demanding operations and short production runs. Automatic crowning works in real time, adjusting pressure so that every part is perfect—regardless of material or bending length.

As a result, errors are eliminated, scrap is reduced, and production repeatability increases. This solution directly translates into higher quality and measurable savings.

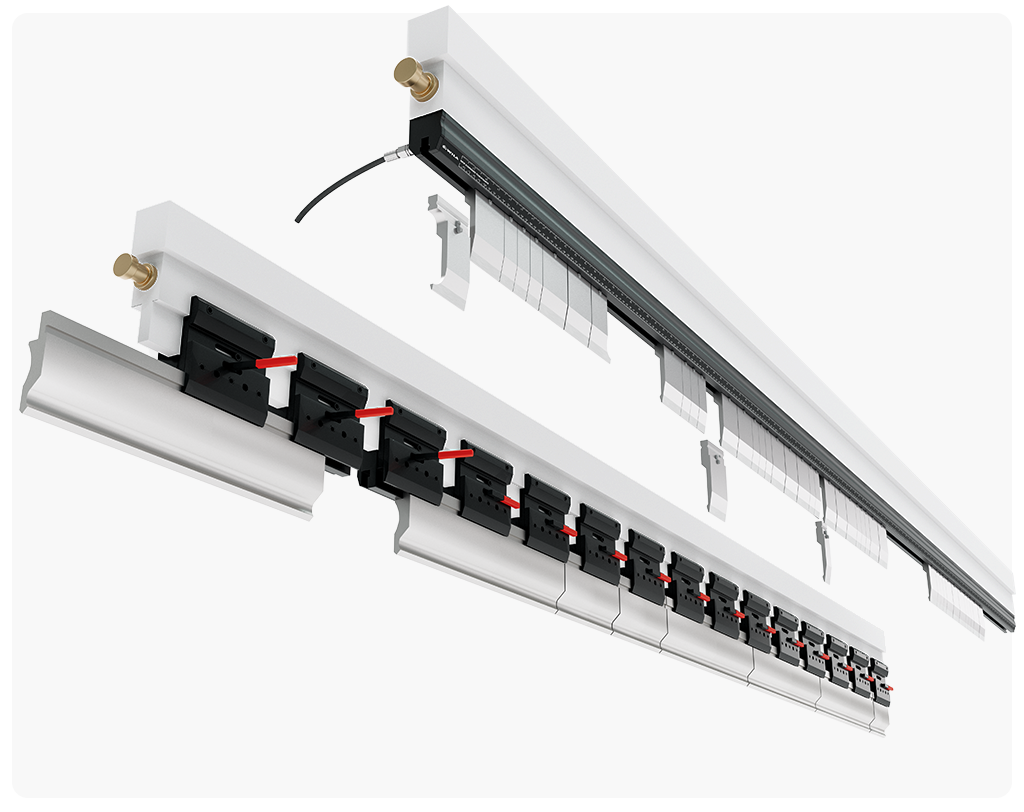

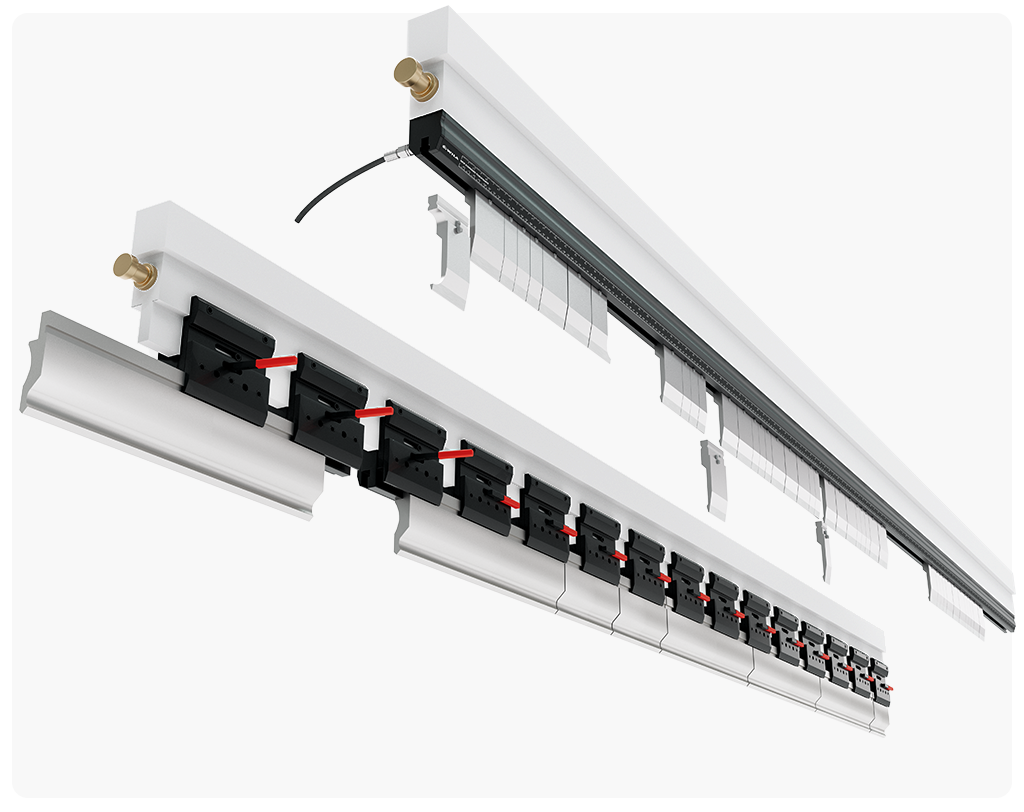

Tool Clamping Systems

Every Otinus press brake is equipped with fast and safe tool clamping systems. The Amada–Promecam system is a proven manual solution that allows tools to be inserted quickly without additional equipment—ideal for users who value simplicity and full control.

The Wila system uses advanced hydraulics: with a single click on the control panel, the tool is automatically clamped in place. This reduces setup time to an absolute minimum while ensuring maximum stability during operation.

Both systems are designed for intensive daily use and reliability, and when combined with a wide range of tools, they significantly improve working comfort and speed.

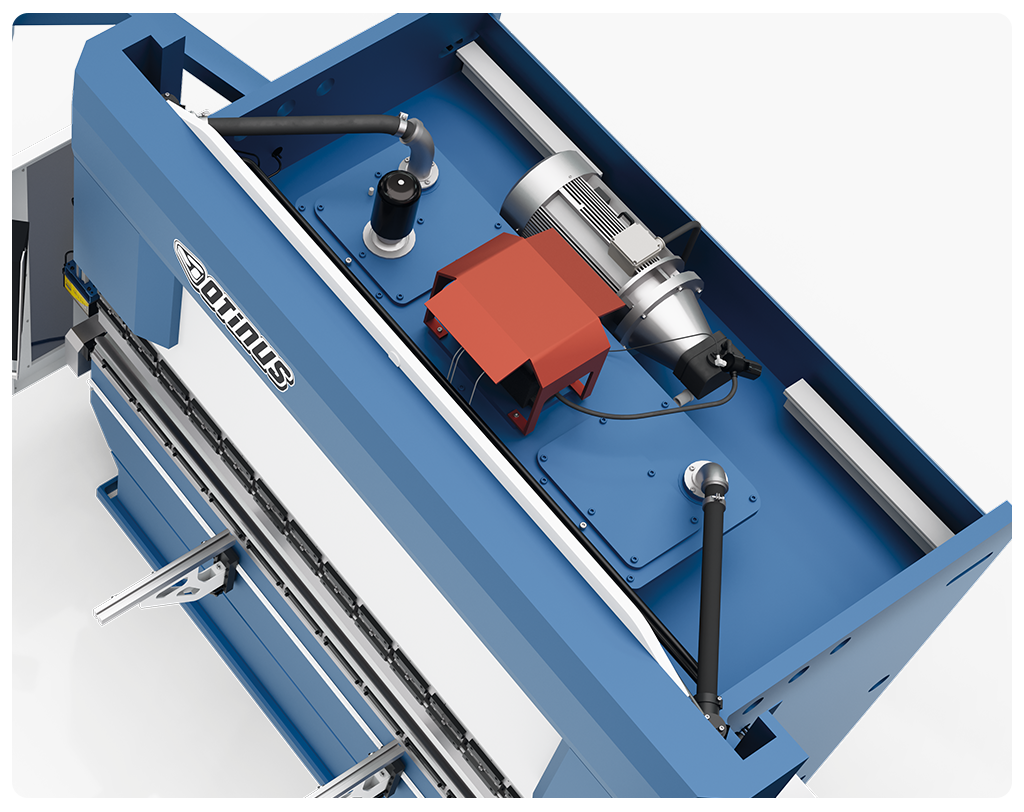

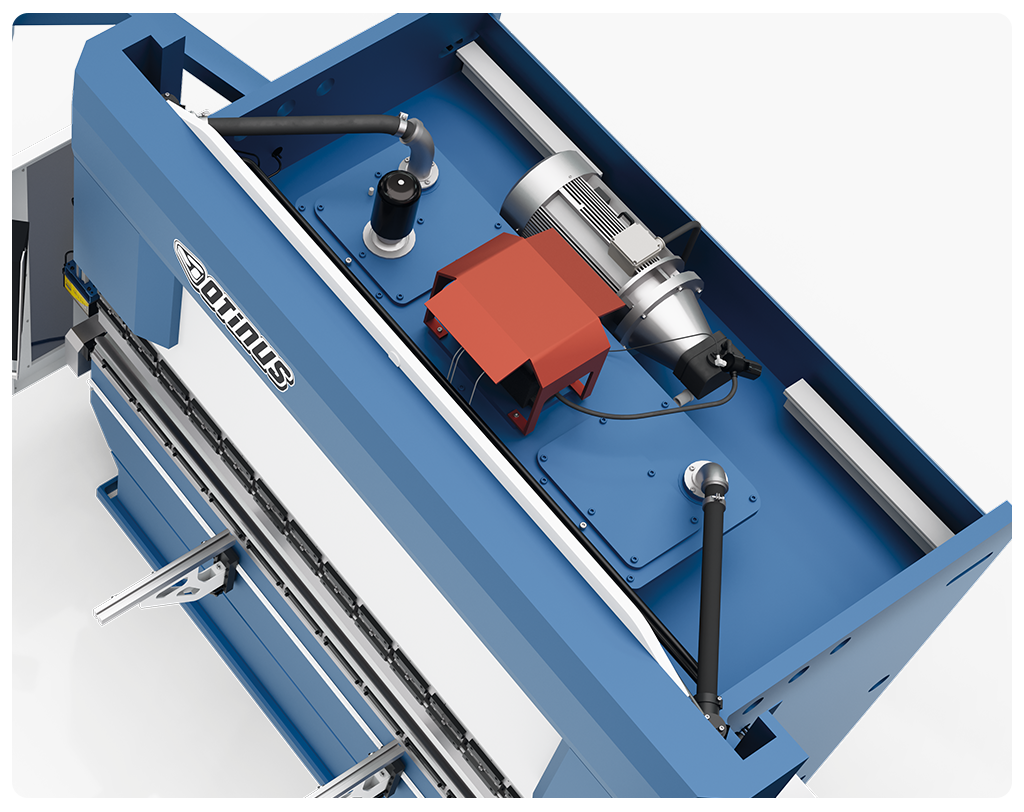

Highest Component Quality

Otinus press brakes are built exclusively with proven, branded components that guarantee reliability and long service life. The hydraulic system is based on valves from the renowned German company Rexroth, synonymous with precision and durability.

Schneider electrical components ensure stable control system operation, even in demanding industrial environments. Safety elements come from industry leaders Omron and Schneider, ensuring full compliance with strict health and safety standards.

Instead of traditional rubber hoses, we use steel hydraulic connections, eliminating the risk of leaks while improving safety and workplace cleanliness. With this configuration, your machine will not let you down—even in intensive, multi-shift operation.

BASE and PRO Controllers

Otinus Base press brakes are equipped with modern controllers that combine ease of use with extensive programming capabilities. The proprietary OT-41 system with a touchscreen automatically calculates bending angles and allows thousands of programs to be stored, ensuring fast and reliable operation.

Optionally, the Delem DA-58T controller expands functionality with advanced programming features, automatic crowning, and full bending simulation.

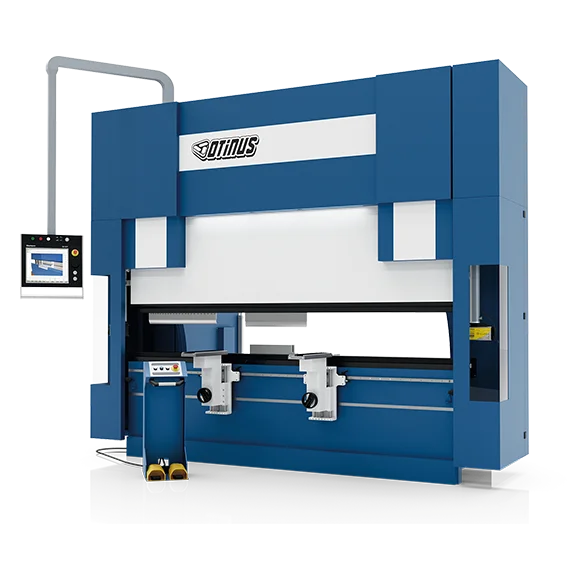

Otinus Pro press brakes deliver the highest level of automation and precision thanks to Delem DA-66T and DA-69T controllers. These premium systems offer 2D/3D graphical programming, multi-axis control, automatic collision detection, and full integration with Delem Profile-T3D offline software.

Regardless of the selected model, every Otinus control system ensures smooth, safe, and efficient operation—perfectly suited for both small workshops and modern production facilities.

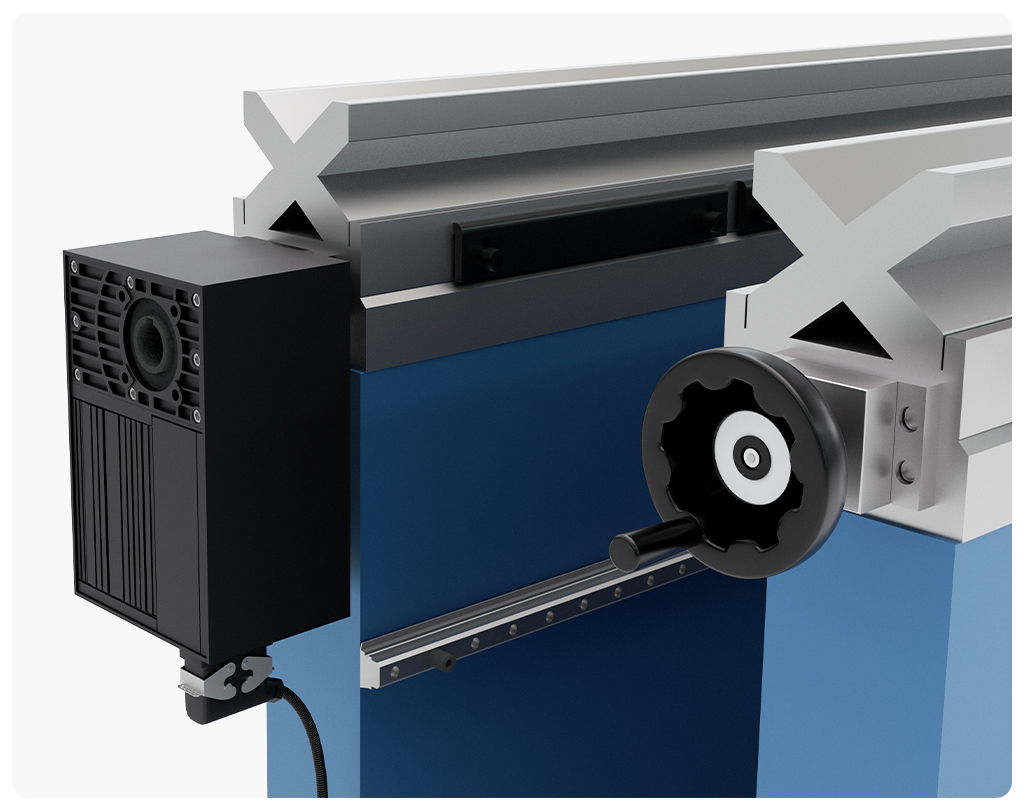

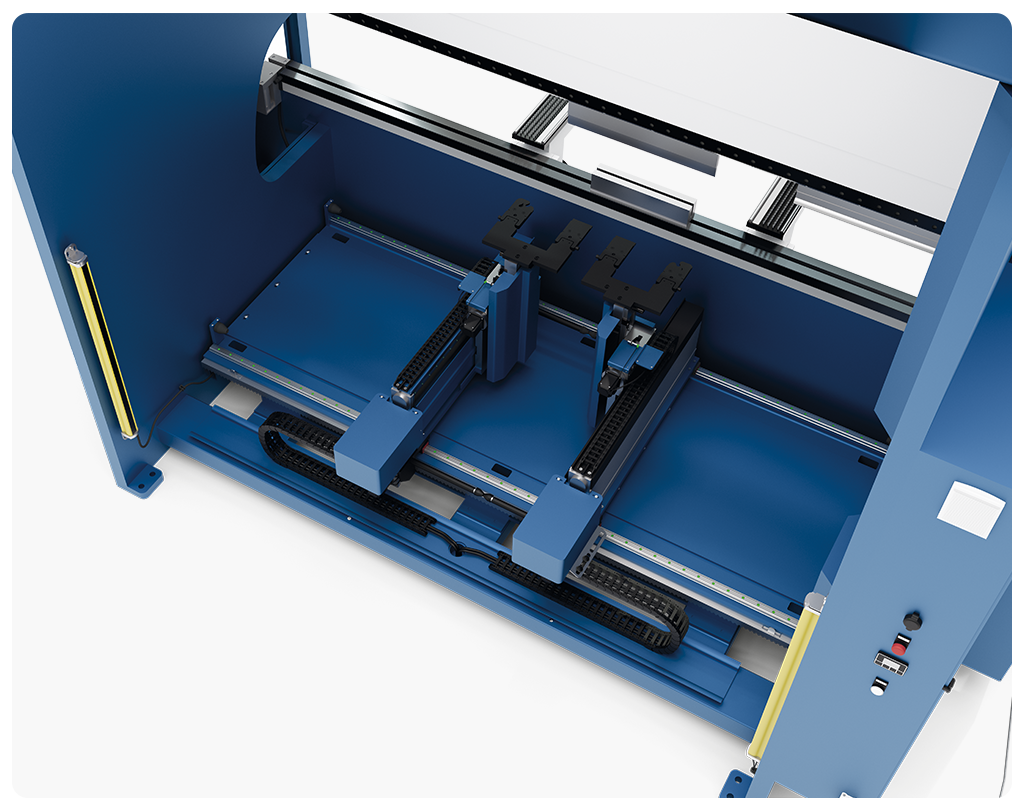

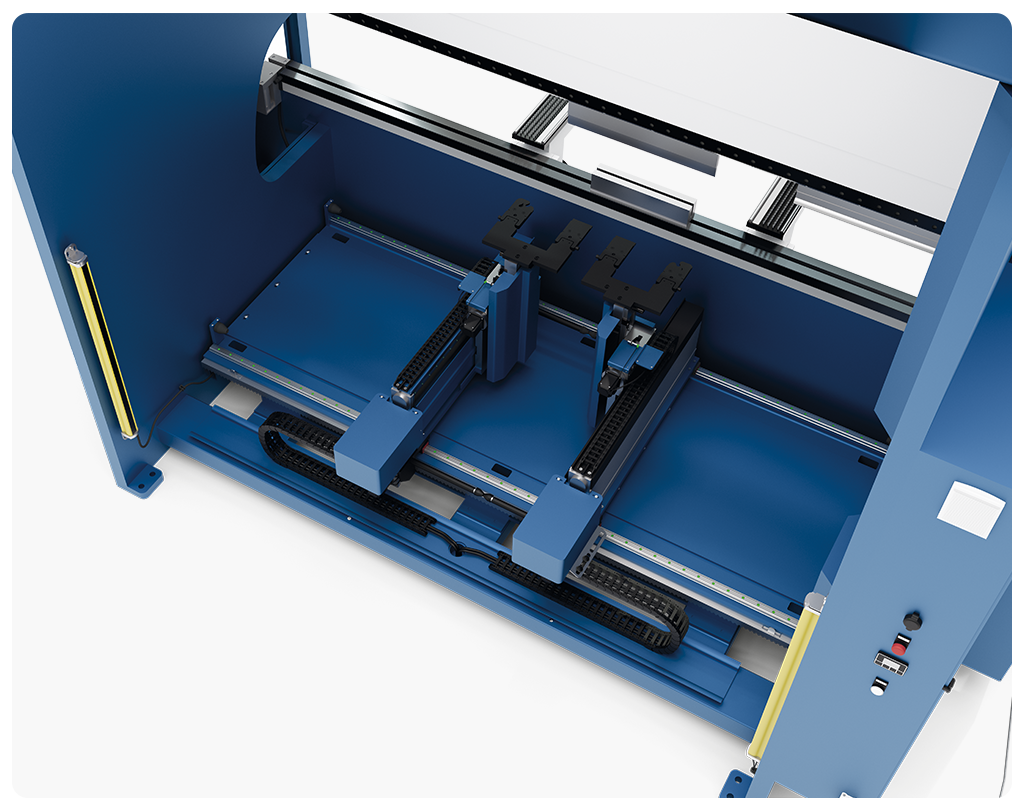

Backgauge

Every Otinus press brake is equipped with an automatic backgauge responsible for accurate sheet positioning relative to the tooling. Servo-driven movement enables smooth multi-axis positioning, significantly reducing setup time and eliminating human error.

The system guarantees full repeatability even for complex bending geometries and high cycle volumes. This allows the operator to focus on quality and productivity, while the company benefits from process stability and reduced material waste. It is an industrial-grade solution that genuinely increases production efficiency.

Schedule a Machine Demonstration

Safety at the Highest Level

Operator safety and production stability are the foundation of every machine investment. That is why our press brakes are designed to provide full user protection in accordance with European CE standards and global industrial best practices.

We do not just meet requirements—we go a step further by implementing solutions that minimize daily operational risks and ensure complete user comfort. Our safety systems do not interfere with work; on the contrary, they simplify it and eliminate unnecessary stress. Every machine is delivered with full documentation, and safety features are standard—not optional.

Over 1,200 companies have already trusted us

Professionals choose us

Every time a question arises, I receive a precise and reliable answer, which always helps me diagnose and eliminate a given problem.”

Also check out dozens of other positive reviews from our customers