Otinus handheld laser welders are modern, compact devices designed for welding and cutting, and in 3-in-1 versions also for metal cleaning. They use fiber laser sources with power ranging from 1000 to 3000 W, offering a wide range of weldable material thicknesses (e.g. carbon steel 3–8 mm and aluminum 2–7 mm). The machines feature an integrated cooling system, an ergonomic welding gun with focal length adjustment, and a long fiber cable that ensures freedom of operation even on large workpieces.

The welders are supplied as a complete set with a wire feeder, nozzles, and accessories, and the price includes installation and one day of training. Thanks to a minimal heat-affected zone, the devices produce clean and aesthetic welds, reducing deformation and the need for finishing work.

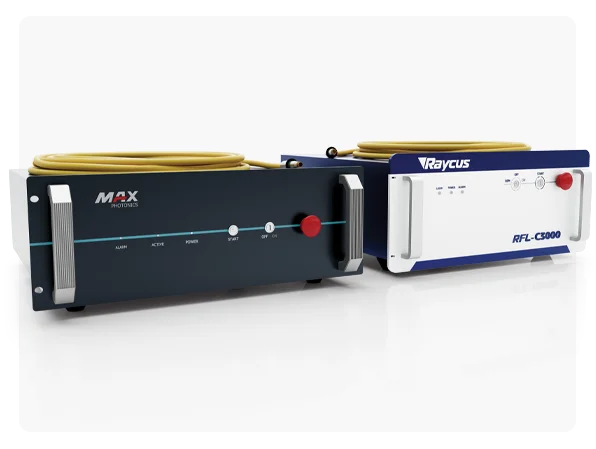

The welders use fiber laser sources from renowned manufacturers. As standard, MAX Photonics sources are used—established in 2004 and known for high quality and operational stability. The company has been developing fiber technologies since 2007 and offers sources with power up to 40 kW.

In 3-in-1 versions, a Raycus source is also available. Raycus manufactures lasers for cutting, welding, brazing, and marking; its devices are used in the automotive, aerospace, medical, and electronics industries.

Some configurations use RayTools or Gefasst (SUP 20S) heads with adjustable focal length; in the Relfar FWH20-S10A versions, a 3-in-1 head is available that enables welding, cutting, and cleaning. The wide selection of sources and heads allows the machine to be precisely matched to production needs.

The integrated water cooling system maintains a stable temperature for both the laser source and the welding gun. This allows the device to operate continuously, even in three-shift operation, while maintaining full performance and long component life. Constant temperature control minimizes the risk of overheating and ensures process repeatability under heavy production loads.