Only basic information about the company owners and the declared revenue from the last two financial years are required. The process does not require submitting full financial documentation or certificates from the Social Insurance Institution (ZUS) or the Tax Office.

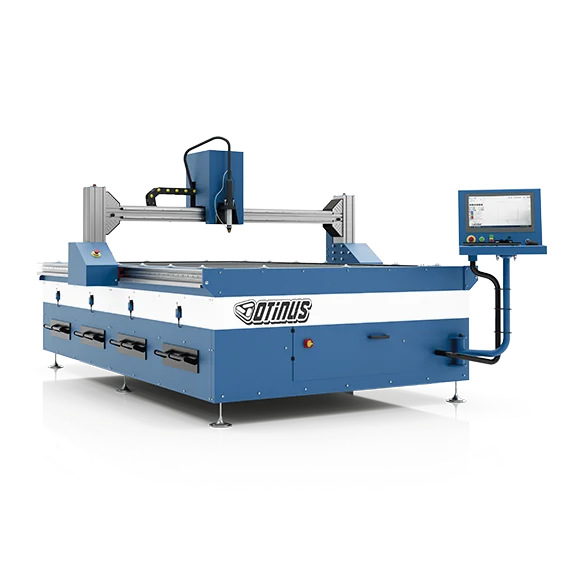

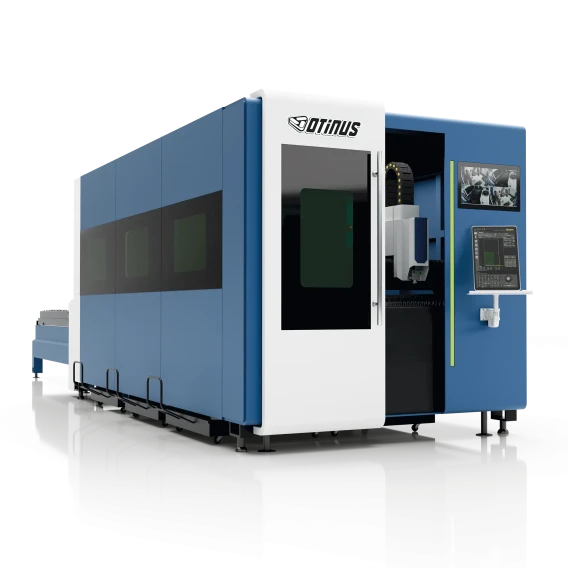

Learn more Check out our other cutting machines

Over 1,200 companies have already trusted us

Professionals choose us

Every time a question arises, I receive a precise and reliable answer, which always helps me diagnose and eliminate a given problem.”

Also check out dozens of other positive reviews from our customers